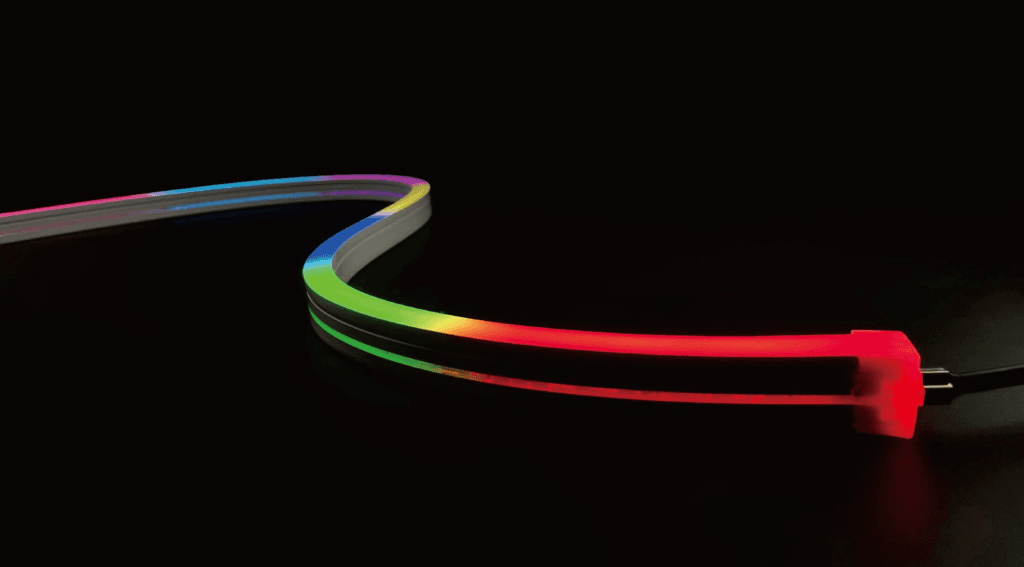

LED strip lights are gaining rapidly popularity for commercial, residential, and industrial commercial lighting. The high lumen efficiency, easy installation, and low maintenance requirements make them very attractive. Additionally, you can customize LED strip lights for any shape or size, making them suitable for a variety of lighting needs.

1.What is an LED Strip Light?

An LED strip light is a flexible circuit board with a series of SMD (surface-mounted) LEDs and resistors attached. Also known as tape lights, they can feature digital LED and can emit white light or all different colors. LED strip lights are 80% more efficient than traditional halogen bulbs, release less heat which can be dissipated easily. Despite their small size, they can produce a good amount of light to brighten any space.

2.Features of LED Strip Lights

LED strip lights offer several key features that make them ideal for various applications:

1.Efficiency: The lumen efficiency of the led strip lights can achieve at least 80lm/w and even higher than 100-130lm/w if the high quality led chips are used.

2.Flexibility: They can be cut into to different lengths and installed in different shapes.

3.Low Heat Release: LED strip light produce less heat, which is safer and more environmental protected

4.Wide Application : Suitable for homes, offices, buildings, vehicles, and more.

3.LED Strip Lights Manufacturing Process

As the demand for LED strip lights grows, the manufacturing process has become more streamlined. Essentially, LED strips are printed circuit boards (PCB) assembled using Surface Mount Technology (SMT). Here’s a detailed look at the manufacturing steps:

Step 1: LED Reel Production

The first step involves placing LED and other components onto a reel. This ensures efficient pasting on the board later.

Regularly we use use equipment to fix LED wafers onto a reel with wire bonds, which is made from industrial gold for longevity. A spectrophotometer sorts LEDs by current, voltage, and color, ensuring consistency. After this, the LED reels are vacuum-sealed to protect them from dust and humidity.

Step 2: Solder Paste Printing

The PCB is prepared for component mounting through a process called Solder Paste Stenciling. This involves applying solder paste, which contains tiny metal balls primarily made of steel with traces of silver and copper, to the PCB at precise locations where the components will be placed. Technological advancements have automated this process, ensuring accurate and consistent application.

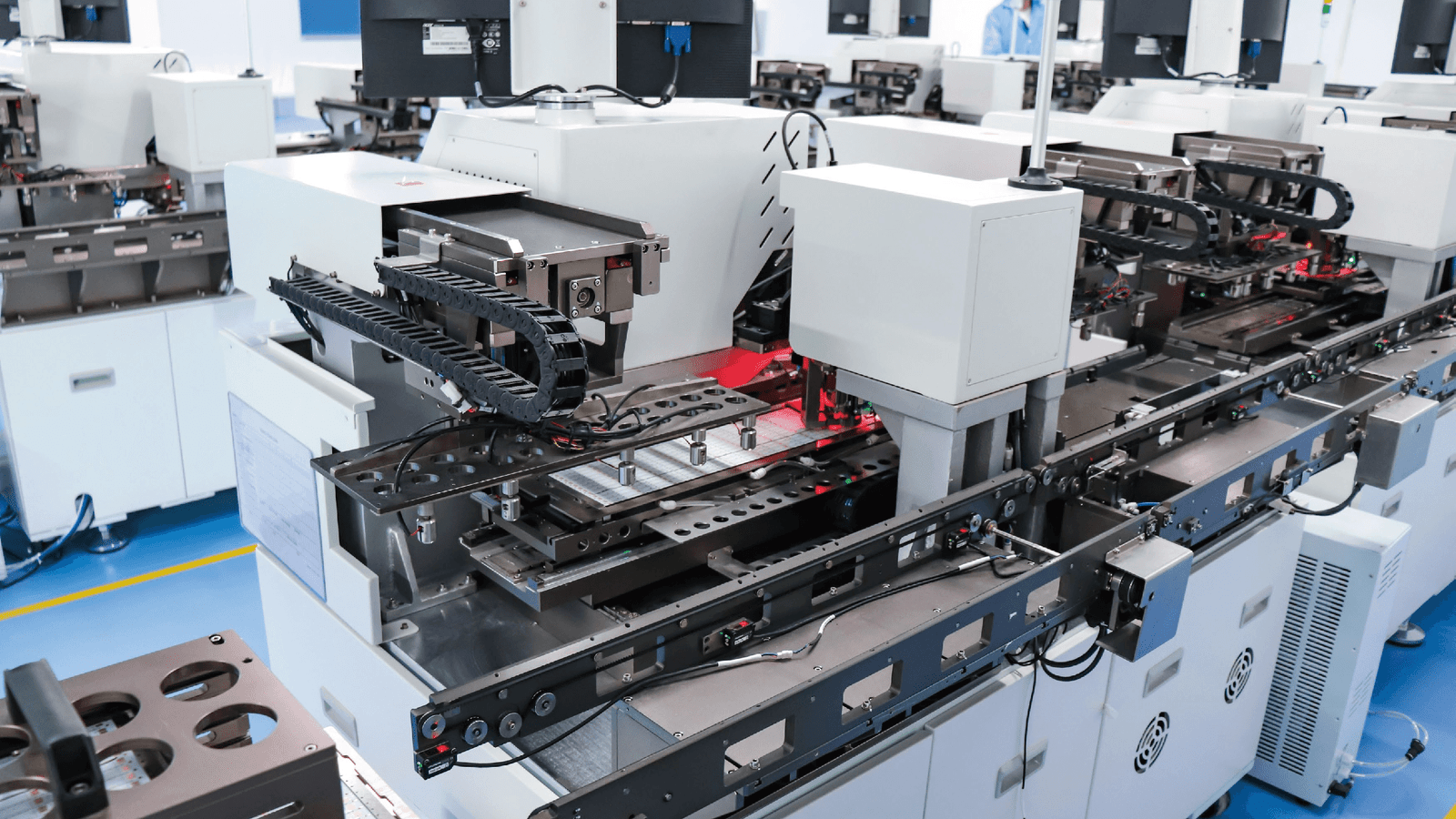

Step 3: Component Placement

The SMT machine then positions the components on the PCB. LEDs from the reel are placed on the PCB using a robotic device like a pick-and-place robot, ensuring accuracy and maintaining quality standards.

Step 4: Reflow Soldering

With the components in place, the PCB undergoes a reflow soldering process. It is passed through a reflow oven equipped with a series of heaters that gradually raise the temperature to 250 degrees Celsius (480 degrees Fahrenheit), causing the solder paste to melt. The board then moves through coolers, which solidify the solder and form permanent bonds.

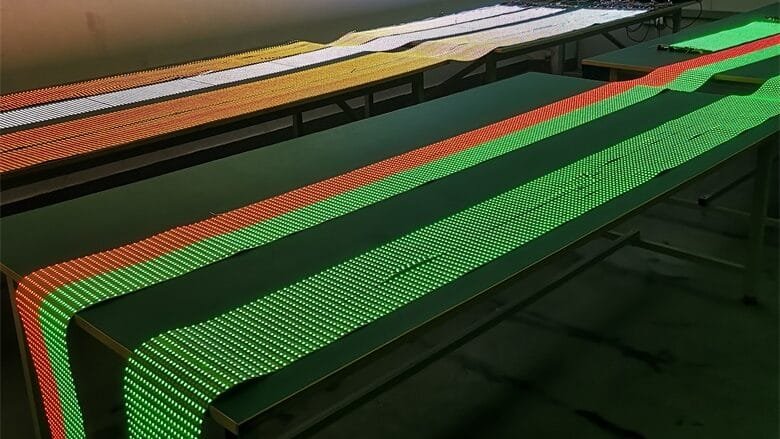

Quality Tests:

- Brightness, color, and specification inspection

- Optical and electrical tests to ensure compliance.

Step 5: Welding

The LED strips come out as 60 cm sections and are welded together using advanced robotic welding arms to achieve the desired length. This ensures high quality and reliable connections.

Quality Tests:

- Lighting tests for loose circuits.

- Comprehensive optical and electric tests.

Step 6: Aging and Waterproofing

The LED strips undergo an aging process, being lit for 12 hours straight to check for seamless performance. They are also waterproofed using silicone, plastic, or both, applied either manually or by machine, to extend their longevity.

Quality Test:

Surface inspection to ensure quality and performance.

Step 7: Tape Pasting and Packaging

After passing all quality checks, 3M tape is applied to the back of the LED strips for easy installation. The final step is packaging the strips for shipment.

4.Things we need to consider when we make the qualified LED strip lights

Quality is very important when it comes to LED strip lights. Here are some key factors affecting their quality:

When creating high-quality LED strip lights, several factors need to be carefully considered to ensure performance, durability, and customer satisfaction. Here are the key considerations:

- Component Quality

LED: Use high-quality LEDs that offer consistent brightness and color. Poor-quality LEDs can lead to color inconsistencies and a shorter lifetime.

Resistors: Choose reliable resistors that can handle the current and maintain the stability of the LED strip.

PCB: High-quality printed circuit boards ensure proper electrical connections and heat dissipation. - Copper Quality in PCBs

Thickness: Ensure the copper wires in the PCB are thick enough to carry the required current without significant voltage drops.

Purity: Use high-purity copper to maintain efficient electrical conductivity and prevent performance issues. - Phosphor Quality in LEDs Brightness and Purity: High-quality phosphor in LEDs enhances light brightness and color purity.

- Manufacturing Process

Precision in Component Placement: Use advanced machines to ensure accurate placement of components on the PCB. - Thermal Management

Heat Dissipation: Design the LED strips to dissipate heat effectively, preventing overheating and extending the lifespan of the LEDs.

Materials: Use materials that provide higher efficient heat management, such as aluminum-backed PCB. - Waterproofing and Durability

Waterproof Coatings: Apply silicone, plastic, or other waterproof coatings to protect the LED strips from moisture and dust.7.Regulatory Compliance - Safety Standards: Ensure the LED strips meet industry safety standards and certifications.

5.Conclusion

Good quality LED strips can provide a reliable and long-lasting lighting solution. It’s essential to do thorough research before making a purchase. If you have any questions about our LED strips or LED strip light profiles, feel free to contact us.